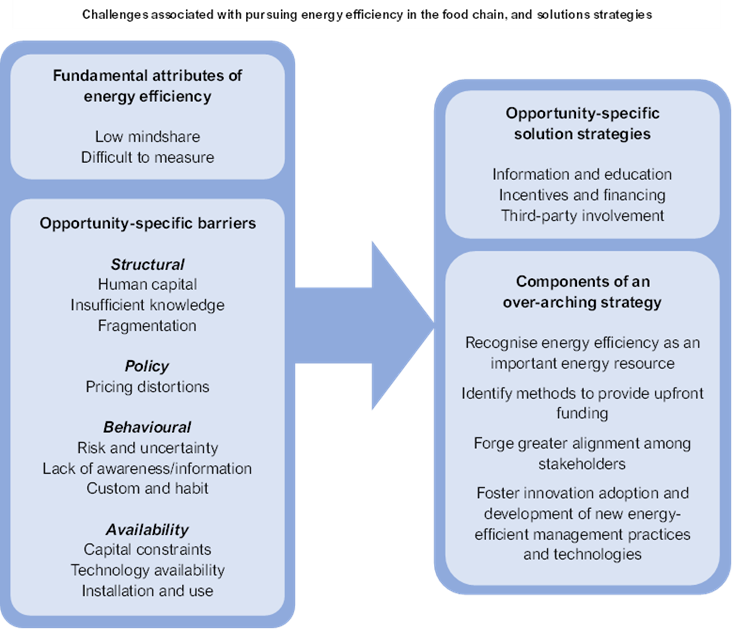

Many of the barriers that prevent investments in energy efficiency are common across various industrial sectors. Certain challenges are fundamental attributes of energy efficiency, such as low mindshare, or difficulties to measure said energy efficiency; other challenges are more opportunity specific.

Indeed, lack of human capital, insufficient knowledge, fragmentation and lack of technical capacity are significant structural challenges that affect the agrifood industry. Political and policy-related challenges, such as limited knowhow of policy makers, organisational and institutional gaps and overlaps, and pricing distortions only further exacerbate these fundamental and structural challenges.

Many behavioural challenges also slow down attempts to induce energy efficiency measures: risk and uncertainty, lack of awareness/information about energy efficiency amongst consumers and the financial sector, custom and habits which perpetuate energy inefficiency. For example, real energy efficiency gains are often perceived by companies as only possible through high-cost technological investments. However, estimates from several studies – both of the agro-food sector and other industries – indicate that on average, energy savings of 20-30% can be achieved using operational changes alone, such as procedural and behavioural changes, without capital-intensive investment.

It is true that capital constraints, technology availability, and installation and use of technology pose major challenges in the adaptability of solutions to the agrifood industry, but solutions to these challenges can be found in opportunity-specific strategies, as well as over-arching strategies.

There are numerous, well-developed management practices and technologies which can be used to reduce the amount of energy currently used in food production. In many cases, the implementation of these approaches is a “win-win” situation for the producer, as the energy cost reductions achieved through implementation quickly repay the capital investment that is required. In the majority of cases, a payback time of five years or less can be achieved and, for a significant proportion of the technologies, the payback is three years or less.

Energy use from waste in the food chain can essentially be reduced through a combination of improved technological, legal and consumption efficiencies, as well as through an increase in re-use, recycling and use of energy conversion technologies at all stages of the chain. Fostering the innovation, adoption and development of new energy management practices and technologies is one over-arching solution currently being targeted by the AENEAM project. The challenges associated with pursuing energy efficiency in the food chain, and the solutions strategies available to address these challenges are highlighted in the figure below.